Why do you like to pilot your aircraft? If we were to guess, it has more to do with the joy and thrill of flying an aircraft and not so much to do with the anxiety brought on by doubt about your plane’s engine health. After all, it’s something that can change rather quickly with situations like pre-detonation or excessive thermal load, both of which can be difficult to catch without lots of experience or the correct instrumentation. Plus, not every pilot cares to know the specifics of how an airplane engine gets them up in the air; many just want to be up there for the ride.

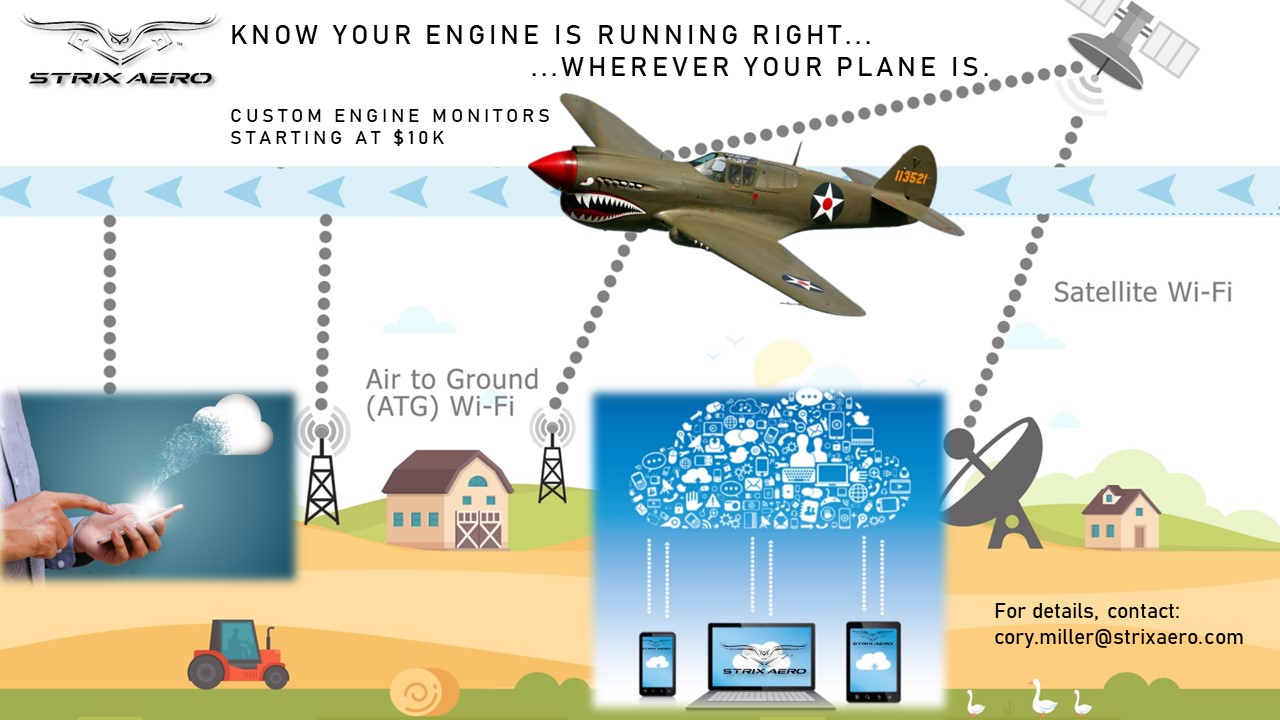

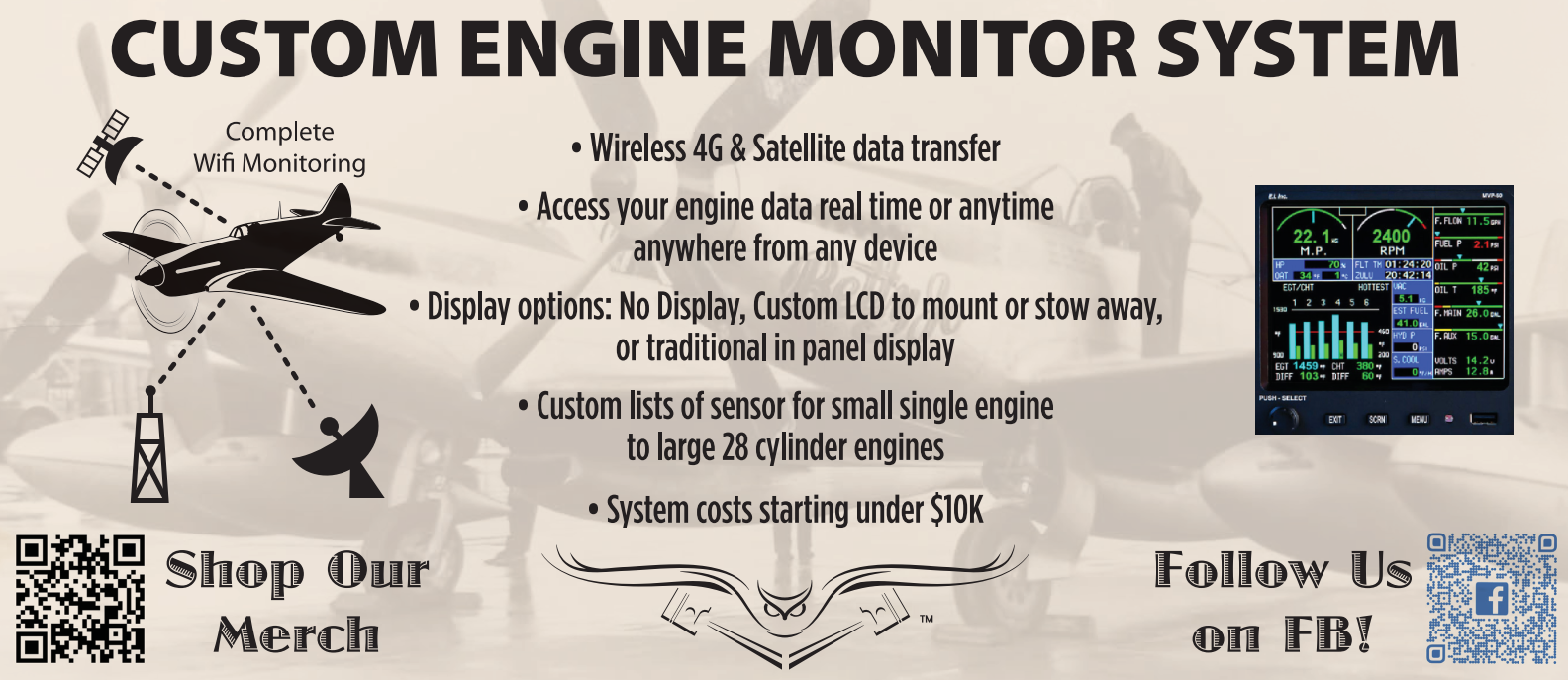

No matter where you fall on the spectrum of aviators, you don’t have to solely rely on your mechanical expertise to know the status of your engine. With the proper tooling such as an engine monitoring system, even a pilot who knows little more than “suck, squeeze, bang, blow” can have a confident bearing on their engine’s health during their flight. And, with a system capable of 4G and satellite wireless data transfer, the ground crew can keep track of the engine’s status without having to fuss with an SD card. The point of an engine monitoring system on piston engine aircraft is not to replace the knowledge that experience brings, but instead to supplement it for a faster, safer response. Let’s explore how important a system like this can be for any piston-engined airplane.

What Happens When Airplane Engines Fail?

It’s an experience no pilot would wish on any aviator, but is nonetheless a reality. How real is that risk, might you ask? In the five-year span across 2019 and 2023, the NTSB reports over 6,800 incidents, accidents, and occurences in civil aviation. Of the 4,800 incidents that offer data on probable cause, over 1,200 mention the aircraft’s engine as part of the cause of the incident. Given the timespan, that’s an average of more than one engine-related incident per day, every day, for five years. This is principally why piloting through an engine failure is taught during flight school. No one wants to deal with one, but every pilot should know how.

So, what happens if an aircraft engine failure happens during a flight? If all engine power is lost while the plane is airborne, the plane will lose the ability to gain altitude and will be forced to glide.With any luck, the pilot will be able to guide the plane to a suitable landing location. The length of time a plane can glide for entirely depends on its drag ratio (altitude lost over distance traveled in this instance) and the altitude at which it lost engine power. While losing engine power doesn’t necessarily mean a crash landing will occur, the risks from losing maneuverability are far greater, especially if a runway is out of range.

How Can Aircraft Engines Fail?

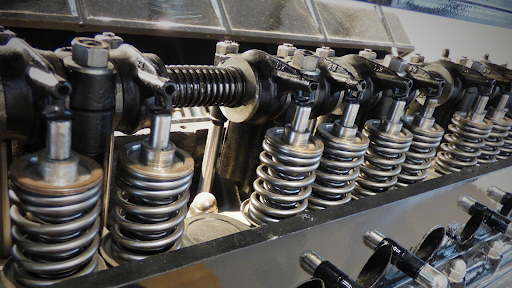

Aircraft engines are incredibly complex pieces of machinery with many points where they may fail. Turbine engines have proven to be much more reliable than their piston engine counterparts, but both have weaknesses and vulnerabilities. One of the most common failures among hobbyists and recreational fliers (most of whom pilot piston-engine aircraft) is fuel starvation due to poor flight planning. Other causes for failure include fuel contamination, oil starvation, damage from foreign objects, structural failures, and mechanical failures to name a few.

So, if you ever have questions about why tracking flight hours and maintenance schedules is so important, these potential failure points are the reason. However, even with proper maintenance and strict adherence to overhaul schedules, engine failures are still possible. This then begs the question: what can we do about it?

How Can Aircraft Engine Failures Be Avoided?

There is no golden egg that’ll prevent your aircraft engine from ever failing, but there are tools and strategies you can use to mitigate the risk. Foremost, proper maintenance is imperative to sustaining the reliability and durability of any aircraft engine. You’ll hear it time and time again, and for good reason. Proper maintenance will be the single most effective means to reducing premature failures and is well worth the expense.

Once you have that covered, there’s still more you can do to enhance your knowledge of your engine health and extend its lifespan. Enter an engine monitoring system (EMS). An engine monitoring system consists of instrumentation that does exactly what the name suggests; it monitors the status of the engine and can alert pilots to any issues it may find. It can also be used for enhancing engine performance, all in all improving your flight safety. Let’s explore what an EMS can really do for you.

How an Engine Monitoring System is Essential for Your Aircraft Engine

In its most basic form, an EMS is a system that constantly checks engine parameters to ensure they’re within spec. More importantly, an EMS can inform pilots when there are parameters out of spec, such as if pre-detonation is detected or if the air/fuel ratio is excessively lean (or rich). Both of these phenomena can result in catastrophic engine failure if not addressed, and both can also be easy to miss during your typical flight.

An EMS can also be utilized during the maintenance of your aircraft for precise engine tuning thanks to onboard data logging. This is the key to extending engine life, achieving optimal fuel consumption, and reaching perfectly balanced performance. So, it’s rather simple; an EMS allows your aircraft to run as perfectly as possible, benefitting your safety and peace of mind as you take to the skies.

Key Components of an Aircraft Engine Monitoring System

The exact configuration of an EMS on your aircraft can vary, but generally every EMS will house the same core components. These include a variety of strategic sensors, a centralized computer to read the input of the sensors, and some means by which to communicate that information (often a display).

Some of the areas where engine monitoring systems can vary are the form factor they take up in your aircraft and how they deal with the data they gather. This is where we at Strix Aero confidently lead the industry. Our EMS solution is flexible in its form factor in the sense that you don’t have to utilize a standalone display if you’d prefer to not change the look of your cockpit. The data can be sent to your mobile device or computer, and can also be stored for later analysis. Wireless data logging capabilities mean the data your EMS collects can be transmitted in real time to ground-based systems so you can work hand in hand with your maintenance crew. After all, being equipped with advanced tooling only helps if the tooling is used as it was designed, so putting the data in the hands of your engine maintenance team and Strix Aero engine experts earns you the highest chance of catching any issues before they develop into an in-flight engine malfunction. With easy real-time or historical data retrieval during flight and when stationary without the need to manually pull an SD card or data drive, our system makes quick work of assessment, troubleshooting, and optimization.

Which Aircraft Engines Can Benefit Most from an Engine Monitoring System?

With all of the features an EMS can offer, it’s hard to imagine an aircraft that wouldn’t benefit from one. In particular, we find many historic aircraft like WWII warbirds equipped with the Allison V-1710 engine and other piston-engined aircraft are often missing out on the great benefits an EMS can provide. Especially due to the age of these aircraft and their less-reliable engine architectures (when compared to modern counterparts), systems like this are all the more important to ensuring pilot safety while also monitoring the health of the aircraft.

Now, some might argue that adding an EMS to a historic aircraft would be improper for the time period. While it’s true these aircraft were not manufactured with engine monitoring systems, leaning into modern tooling offers us a better opportunity to preserve their history. With it, safety and reliability are greatly increased, both of which are essential to keeping these aircraft airworthy. And, like we touched on, the Strix Aero EMS can be installed in your historic aircraft without changing the look of the cockpit; no panel display is required for the system to operate.

Strix Aero: Your Engine Monitoring System Destination

We at Strix Aero have found our niche in aviation servicing the vibrant community of historic aircraft enthusiasts. We deliver top-notch engine maintenance and restoration services to do our part in safeguarding the history of these magnificent aircraft. At the end of the day, every hobbyist and recreational flier simply wants to enjoy their aircraft and the feeling flying it gives them; we’re eager to do our part in keeping those flights safe and reliable. If you’re keen on learning more about what an engine monitoring system can mean for you and your aircraft, or if you’re looking for other ways to improve the reliability of your aircraft engine, get in touch with us and let’s start a conversation.