An Introduction to Aircraft Carburetor Overhauls

Whether your time between overhauls is coming due or you’re troubleshooting a recurring issue, a carburetor overhaul is sure to come up on the topic of regular engine maintenance and performance optimization. Being purely mechanical and with very few moving parts, carburetors are generally quite reliable, but they will require some careful attention from time to time to keep them operating within spec.

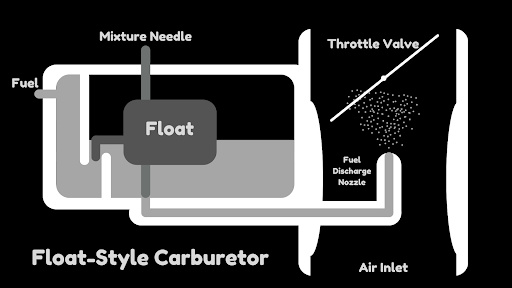

Why is that? Well, the task of mixing fuel and air in the perfect ratio to get the explosive force needed to turn the propeller of your plane is a very precise operation, and it’s handled by some very precise equipment. Most modern engines utilize fuel injection systems that employ a computer to measure the fuel and adjust the air/fuel ratio based on sensor inputs, but carburetors don’t have that luxury. Instead, carburetors use precise engineering and sometimes even the input of the pilot to achieve the proper air/fuel ratio. And while carburetors are an impressive feat of engineering and can be incredibly durable, they’re not infallible.

How do Aircraft Carburetors Fail?

Carburetors can lose performance or fail altogether from a variety of causes. The most common failure point is contaminated fuel, that being fuel which also contains water. When water comes into contact with the small ports and orifices of the carburetor that handle the fuel, corrosion can form and may partially or completely block them, hindering carburetor performance or disabling it entirely. Other parts that can fail will depend on your specific carburetor since there are so many unique designs used in aircraft, but other common failure points are the multitude of sealing surfaces (O-rings, gaskets, diaphragms) and the few moving parts.

What’s Involved in a Carburetor Overhaul?

So, what does a carburetor overhaul look like on an aircraft? The objective of any overhaul is to restore the full functionality of the carburetor so that it operates as it was originally designed. The simplified steps to an aircraft carburetor overhaul are as follows:

- Removal of the carburetor from the engine

- Complete disassembly of the carburetor

- Cleaning, restoration, or replacement of all components

- Reassembly of the newly overhauled carburetor

- Bench flow testing and tuning

- Return of carburetor to engine & system checks

Of note, the bench flow testing and tuning step is the most vital step to ensuring proper operation of the carburetor. This is where the mechanic will verify the core function of the carburetor, precisely mixing air and fuel for combustion, is being carried out as expected and as required for safe operation of the aircraft. Extremely precise equipment is utilized to test and measure fuel delivery relative to air flow, and the carburetor will only make it past this step once it meets the specifications provided by the manufacturer.

How to Know When Your Aircraft Carburetor Needs an Overhaul

So while we’ve covered what a carburetor overhaul is, we will now cover when you might need one. The carburetor for your aircraft’s engine will communicate with you; you will just have to listen to the cues it’s giving. Here are a few signs you can look for to know you might be due for the service:

Engine Starting Issues

Having difficulty getting the engine started may be a sign of carburetor issues. If you’re only able to get it to run with the choke (or primer/fuel enrichment) on, it’s very possible the carburetor isn’t delivering adequate fuel and may be clogged. Or, if the carburetor is extremely out of spec, you may find that the engine won’t start at all.

Rough Idle

If you’re able to get the engine started but notice it has a choppy, rough idle, the carb could be to blame. This will present itself as an inability for the engine to maintain a consistent RPM at idle. You’ll want to look for an idle that bogs at random; for example, a dead miss (where one of the cylinders isn’t firing) would be rhythmic, but a rough idle from improper fuel mixing will result in a random idle.

Reduced Performance

If your aircraft feels to be down on power, it could be that the carburetor is restricting the total power output. A stuck choke or an improper fuel mixture could be the cause, and either way, it’s something you’ll want to have checked before you’re back in the air. Of course, also be mindful of carburetor icing. If you only experience reduced power after you’ve been in the air for a while, the fix could be as simple as enabling carb heat.

Engine Knock/Pinging

If your engine seems to run fine in the lower RPMs but starts to knock or ping as you bring up the RPM, it could be that the carburetor isn’t delivering enough fuel. This then leads to a lean air/fuel mixture and possibly pre-detonation. Pre-detonation can cause catastrophic engine failure, and is most easily recognized by the telltale knocking or pinging sound it makes.

Black Exhaust

A common sign of an air/fuel ratio that’s too rich is black smoke out of the exhaust. That black smoke is a sign that the fuel isn’t being burned completely in the combustion cycle, leaving it to be expelled through the exhaust. You may also be able to smell the fuel. Running an engine in this state can ultimately foul the plugs, and at best you won’t be able to reach full engine power. At worst, it can lead to oil contamination (with fuel), bore scoring, and inoperable spark plugs, ultimately making for an inoperable engine.

Age

Whether or not you’ve kept up perfectly with maintenance on your aircraft, some components simply degrade with age. Carburetor diaphragms are one such component. Over time, these diaphragms can tear, leak, or otherwise fail to perform their function which can result in poor engine performance. The shelf life of aircraft carburetor diaphragms is generally around ten years, at which point it’s a good idea to get a carburetor health check.

Quick Tip for Maximizing the Durability of Your Overhauled Carburetor

After you’ve gone through the effort of getting your carburetor overhauled, there is one key precaution you should take to ensure you won’t have to go through another overhaul anytime soon. The absolute best thing you can do for your carburetor is to be incredibly mindful of your fuel. That’s not only the fuel that is being put in the aircraft, but also the fuel that is onboard while the aircraft is being stored. While aviation fuel is much more stable than automotive fuel and can be stored for longer, you still want to take precautions to prevent moisture/condensation from entering the fuel system. For many, that’s as simple as filling the fuel tanks before storage.

Where to Get an Overhaul for Your Aircraft Carburetor

When it comes time to service the carburetor(s) on your aircraft, you’ll want to find a professional you can trust to handle the job. As we’ve discussed, the carburetor is an essential component to the normal operation of your aircraft, and if it’s not tuned perfectly, your aircraft won’t perform perfectly. We at Strix Aero are the experts for all your aircraft engine care needs. We specialize in restoring and maintaining the functionality of historic aircraft, with our core focus being on engine restoration.

We’ve recently joined forces with KPS Airmotive, taking under our wing a proven team of specialists in aircraft carburetor maintenance and restorations. Following their over 40 years in the business of aircraft carburetion, they were looking to collaborate with a similarly vested crew. Strix Aero presented the perfect match. With their uncontested expertise in aircraft carburetion and our expertise in historic aircraft engine restorations, we come together to offer you a comprehensive suite of services to keep your aircraft aloft and well.

So, whether you’re in need of a carburetor overhaul or your whole engine needs to be looked at, trust the qualified team at Strix Aero with the job. We’ve made our mark on the industry as proven resources and dedicated enthusiasts, and we’re eager to see how we can help you with your aircraft. Give us a call or drop us a message today and let’s get the conversation started.