Allison 17 Engine Overhaul

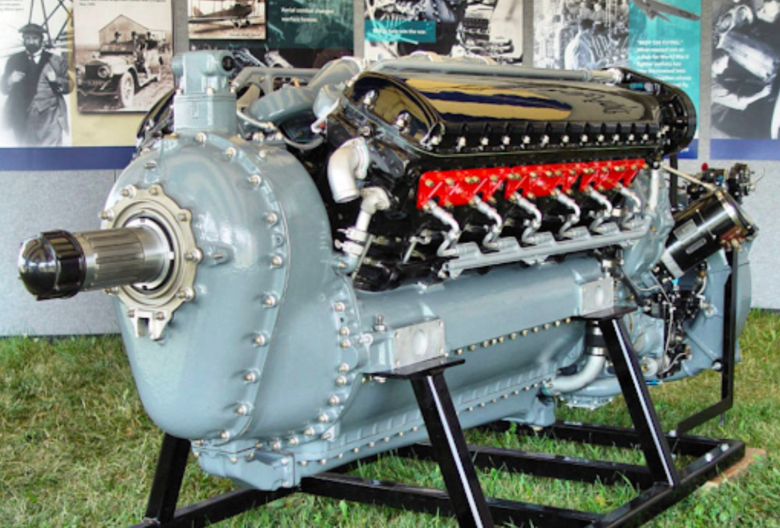

The Allison V-1710 engine is a potent, liquid-cooled V-12 aircraft engine that gained popularity during World War II. Its historical importance and impressive performance capabilities make it attractive to vintage aircraft enthusiasts. However, restoring and overhauling this engine can be a complex and challenging process that requires specialized knowledge and expertise.

Let’s explore the process of overhauling and restoring an Allison V-1710 engine and the services that are available to assist with this process.

Overview of the Allison V-1710 Engine

The V-1710 engine features a V-12 configuration with a displacement of 1,710 cubic inches (28 liters). It uses a liquid-cooling system to maintain operating temperatures and is capable of producing up to 1,500 horsepower, depending on the specific model and configuration. Despite its impressive power and performance capabilities, the V-1710 engine can be challenging to maintain and restore due to its complex design and aging components.

Overhauling an Allison V-1710 Engine

Overhauling an Allison V-1710 engine typically involves a detailed and comprehensive process that is performed by experienced professionals. The process generally involves the following steps:

- Disassembly: The engine is carefully disassembled, and all components are inspected for wear and damage. Components that are found to be worn or damaged are typically repaired or replaced.

- Cleaning: All components are thoroughly cleaned to remove dirt, grime, and other contaminants.

- Inspection: Each component is inspected using specialized tools and equipment to ensure that it meets the manufacturer’s specifications and tolerances.

- Machining: Components that require machining are carefully milled, ground, or otherwise shaped to ensure that they are within the appropriate tolerances.

- Assembly: Once all components have been inspected, repaired, or replaced, the engine is reassembled. The assembly process involves carefully fitting and aligning each component to ensure that the engine operates smoothly and efficiently.

- Testing: The overhauled engine is subjected to rigorous testing to ensure that it meets the manufacturer’s specifications and operates reliably and efficiently.